Profile properties customized to your requirements

Optimize the quality of your products, speed up your processes and maximize your profits. If required, we can supply ready processed profiles with individually definable characteristics all ready for assembly, in line with your specific uses or fields of application. All you need to do is install them.

-

Coating with high-reflection Low-E film

Low-E film 12 ε 3 effectively reduces loss of heat. This allows existing profiles with flag to be optimized without changing their geometry, i.e. without additional development and tooling costs. The Uf values correspond to those of window systems using foam. This means no additional process or logistical input on your part, as the insulating bar is delivered ready coated in film. We offer these coated high-efficiency insulating profiles, which are ideal for energy saving or passive house windows, under the product designation insulbar® LEF

-

Punching with tolerances compliant to DIN ISO 2768-1 m

Profiles can be supplied ex works at low cost with punched holes for drainage, fixing or pressure compensation. This eliminates the need for subsequent punching. Application-specific boreholes or milling operations are also possible, saving processing companies both time and money.

-

Cover profile

Profile areas where no paint is required can be covered by a reusable clip-on additional profile. This reliably protects against unwanted paint application. Cover profiles reduce the work load and ensure reliable results – particularly when working with complex profile geometries.

Profile areas where no paint is required can be covered by a reusable clip-on additional profile. This reliably protects against unwanted paint application. Cover profiles reduce the work load and ensure reliable results – particularly when working with complex profile geometries. -

Dust blasting

Dust blasting is a process used to roughen the surface of the insulating bar. This increases surface energy, improves paint adhesion when powder coating, and ensures a good, durable painted result and an improved appearance. Where even more stringent demands are made on paintability, we recommend using insulbar® ESP, which is made of a material with improved electrostatics for optimum powder attraction, and can also be dust blasted.

Dust blasting is a process used to roughen the surface of the insulating bar. This increases surface energy, improves paint adhesion when powder coating, and ensures a good, durable painted result and an improved appearance. Where even more stringent demands are made on paintability, we recommend using insulbar® ESP, which is made of a material with improved electrostatics for optimum powder attraction, and can also be dust blasted. -

Temperature-resistant foil application

The practical solution for greater fllexibility during powder coating. The foil is used to cover defined areas of the profile during powder coating. Applied prior to paint application, it can be removed again afterwards without leaving any residue.

-

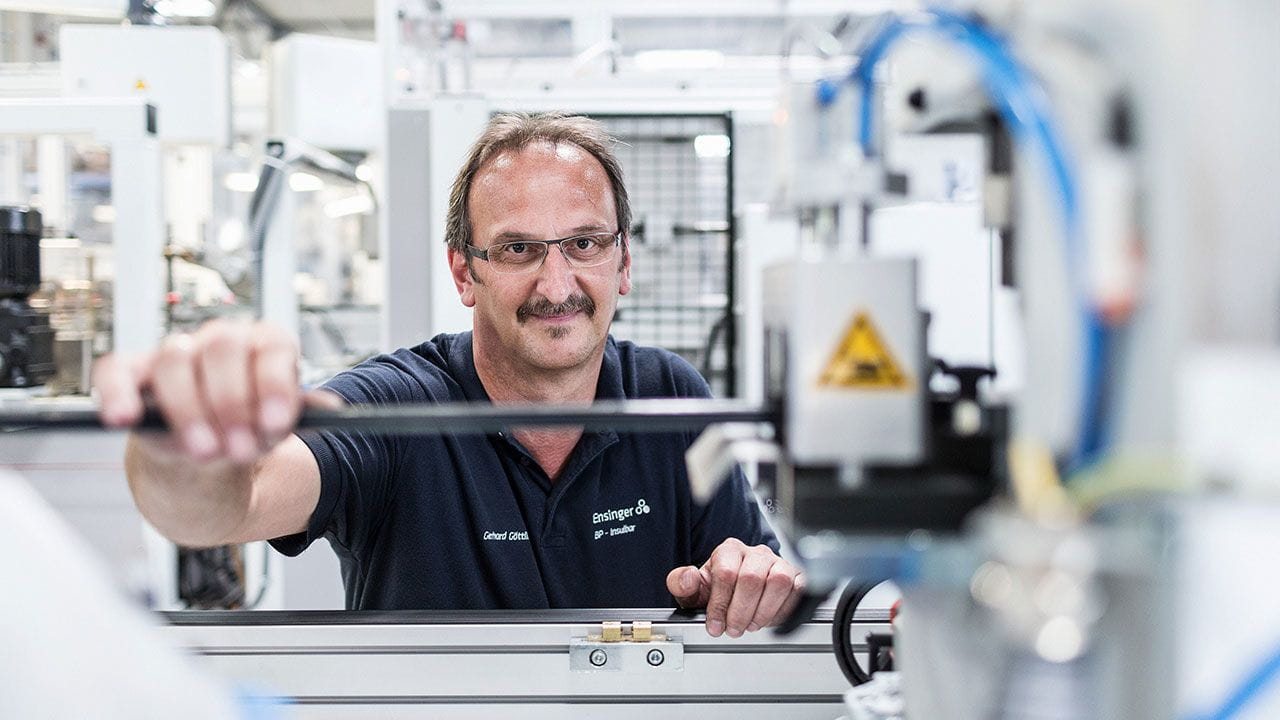

Subsequent machining

In rare application cases in which the tolerances achievable using the extrusion process are not sufficient, we offer subsequent machining of the thermal insulating bars using a high-speed milling station. This enables the achievement of tolerance fields of 0.05 mm, irrespective of the profile size.

In rare application cases in which the tolerances achievable using the extrusion process are not sufficient, we offer subsequent machining of the thermal insulating bars using a high-speed milling station. This enables the achievement of tolerance fields of 0.05 mm, irrespective of the profile size. -

Pointing

To improve the drawing-in behaviour of the insulating profiles into the aluminium cavities, the ends of the profile lengths can be "sharpened to a point". This simplifies and speeds up the automatic introduction of profiles into the aluminium half-shells and so enhances productivity during window and door production.

-

Marking

Using laser or embossing, product markings can be added in certain areas or intervals to customer order. This guarantees the traceability of all relevant data within the framework of optimized quality assurance.

Using laser or embossing, product markings can be added in certain areas or intervals to customer order. This guarantees the traceability of all relevant data within the framework of optimized quality assurance. -

ConditioningThe insulating bars can be conditioned in a warm water bath following production. This enables the moisture content of the profiles to be adjusted precisely to individual requirements. This can simplify post-process machining in the customer's own workshop, for instance. The moisture content depends on the profile geometry, water temperature and conditioning period.

-

Bundling

The insulating profiles are bundled into the required piece numbers to simplify handling. Processors benefit from cost and time benefits during storage, order picking and also during actual processing.

The insulating profiles are bundled into the required piece numbers to simplify handling. Processors benefit from cost and time benefits during storage, order picking and also during actual processing. -

Delivery in coils

System manufacturers and processors whose logistics and processing operations are configured for coils can also be supplied with their profiles in coils where the geometry allows.

System manufacturers and processors whose logistics and processing operations are configured for coils can also be supplied with their profiles in coils where the geometry allows.