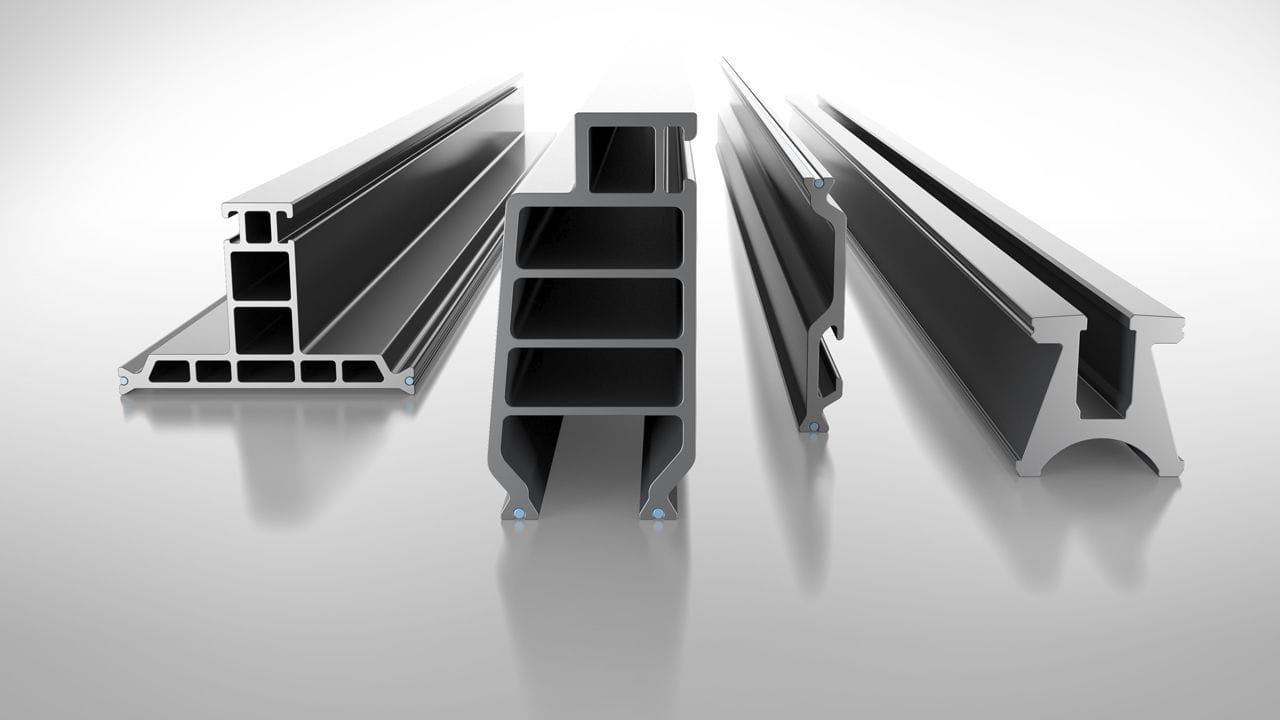

Expertise and technology for perfect insulating profiles

Ensinger combines many years of experience and its unique fund of knowledge in the field of plastics with the very latest findings and proven production techniques. Self-compounded plastics and efficient extrusion methods form a solid foundation for optimum adjustment of insulating bars to the required application. At the same time, they ensure fast, economical production coupled with premium profile quality and narrow tolerances.

-

Compounding - material properties are all about the mix

During compounding, plastic raw materials are melted with fillers or additives - such as glass fibres - extruded into thin strands and then cut into granulate. This process allows the composition of the plastics to be adjusted to specific applications or required profile properties: for example by improving rigidity or increasing electrical conductivity.

-

Extrusion - the material maintains its shapePressure and temperature-regulated extrusion is a continuous production process in which plastics are plastified in an extruder and then forced at pressure into the required shape through a specially shaped die. The cross-section of the produced geometric shape equates with the used die or calibration. The extrusion process is an efficient method which is ideally suited for the manufacture of plastic profiles.

-

Process expertise - for optimum results

To make sure that the insulating profiles possess the required properties and product benefits, alongside the technology used, experience and a solid fund of knowledge are vital. The turbulence process during extrusion for instance ensures even orientation and distribution of the glass fibres in the plastic profile - so offering the assurance of high transverse tensile strength.

-

Tools - to suit every batch size

The tools used for production of thermal insulating bars are developed and manufactured at Ensinger on a profile-specific basis. Depending on the piece numbers or required production quantity, a distinction is made between tools for mass production and tools for small production runs.

Tools for mass production:

- The customer invests only once in the initial tooling, eliminating follow-on or repair costs.

- Lasting adherence to tolerances, even with extremely high delivery volumes per tool.

Tools for small production runs:

- More economical, simpler and faster manufacture than for tools used in mass production, but limited production quantity.

- Ideal for the production of sample profiles.